Stratasys F123 Series

The Stratasys F123 Series is the ultimate, all-in-one rapid prototyping system for your entire team. It combines the power of FDM with the ease of GrabCAD Print for the most versatile and intelligent solution available.

The new Stratasys F123 Series is easy to operate and maintain for all levels of experience. And, it's adept at every prototyping stage, from concept verification to design validation to functional performance.

The most commonly used CAD file formats can be imported directly into GrabCAD. The three printers in the platform, the Stratasys F170, F270 and Stratasys F370, support a broad range of capabilities and budgets for every stage of prototyping.

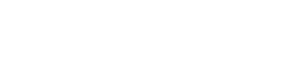

Minimal setup means you can simply plug and play to give your entire office access to professional 3D printing.

Auto-calibration ensures you spend less time troubleshooting and more time prototyping.

Fast and easy material swaps help maximize your design team’s productivity.

Rapid Prototyping with the F123 Series

CONCEPT VERIFICATION

Rapidly and cost-effectively iterate concept verification models in Fast-Draft Mode using PLA material that offers unbeatable costs savings at the professional level.

DESIGN VALIDATION

Validate the fit, form and aesthetics of complex designs and assemblies with more accuracy than ever before with the superior resolution and consistency of the F123 Series.

FUNCTIONAL PERFORMANCE

Test the functional performance of your prototypes in real-world conditions using a variety of robust thermoplastics including ABS, ASA and PC-ABS.

OverviewSpecificationsSoftware

Materials

Versatility & Performance

The Stratasys F123 Series lets you print everything from fast, low-cost concept models to durable assemblies. And the Stratasys F123 Series gives the option of up to four different materials, along with our easy-to-remove soluble support material.* Create complex parts and assemblies with no compromise on accuracy, detail and repeatability. Even for your earliest design iterations, you can expect Stratasys quality and dependability.

*The Stratasys F170 and F270 models support PLA, ABS-M30, and ASA materials; the Stratasys F370 supports PLA, ABS-M30, ASA and PC-ABS materials. PLA uses breakaway support only.

Specifications: System Size and Weight

Build Size

- Stratasys F170: 10 x 10 x 10 in.

- Stratasys F270: 12 x 10 x 12 in.

- Stratasys F370: 14 x 10 x 14 in.

Layer Thickness

- 0.013 in. (ABS, ASA, PC-ABS)

- 0.010 in. (PLA, ABS, ASA, PC-ABS)

- 0.007 in. (BS, ASA, PC-ABS)

- 0.005 in. (ABS, ASA, PC-ABS)

Accuracy

Parts are produced with an accuracy of +/- .200 mm (.008 in), or +/- .002 mm/mm (.002 in/in), whichever is greater.

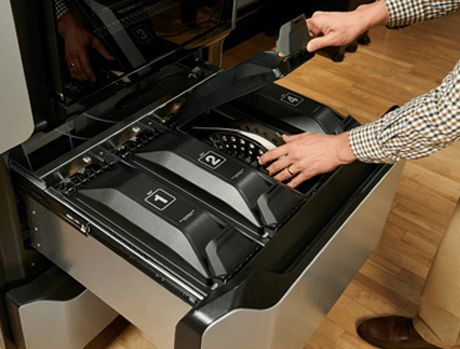

Smarter Software

GrabCAD Print software simplifies the entire 3D printing process with an intuitive CAD-like application anyone on your team can use. Features like detailed reporting and remote monitoring help you easily manage your print jobs from outside the office. Combined with the ability to seamlessly share projects between users, it all adds up to a more streamlined, efficient workflow.

More Information

FDM System & Material Overview

FDM 3D Printers use a variety of engineering-grade thermoplastics to manufacture functional parts. FDM thermoplastics are environmentally stable, so overall shape and part accuracy don’t change with ambient conditions over time. Materials are easy to change with no mess or complicated processes.

Science, Technology, Engineering & Mathematics

By 2018, the U.S. will have more than 1.2 million unfilled jobs in the areas of science, technology, engineering, and math (STEM) because there will not be enough qualified workers to fill them. STEM is where jobs are today and where the job growth will be in the future.

Through activity-, project-, and problem-based curriculum, our programs give students a chance to apply what they know, identify problems, find unique solutions, and lead their own learning. When students understand how their education is relevant to their lives and future careers, they get excited, and are more successful.

Students gain knowledge and skills in the following STEM areas:

- Engineering design process

- Industry standard 3D modeling software

- Using an engineer’s notebook

- Mechanisms, energy, statics, materials, and kinematics

- Development of residential and commercial properties and structures

- Project research, testing and validation techniques