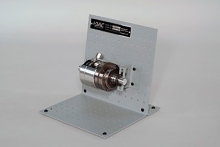

DAC Worldwide’s In-Line Friction-Type Pneumatic Clutch Cutaway (200-2202) depicts a sectioned industrial pneumatically-activated, spring-return, in-line, friction-type clutch for use in a classroom and laboratory training related to mechanical drives.

DAC Worldwide

DAC Worldwide, a US-based world leader in technical training solutions has been helping maintenance departments, training professionals, vocational educators, and workforce development specialists with realistic, hands-on training systems for over 35 years.

DAC Worldwide has a wide range of products to help you build custom courses to meet your industrial training needs. The cutaways provide a better understanding of how components actually work, which is great for teaching both fundamentals and troubleshooting. The dissectibles teach essential hands-on skills for disassembly and assembly. Finally, the models allow you to explain how the various components of a system work together to create an entire process.

-

Mechanical Clutch Training AidItem Number:200-2202

-

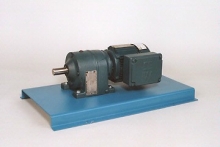

Realistic, Hands-On Skill BuildingItem Number:205-230

In-line helical gear reducers have a unique set of benefits. They’re useful in higher horsepower applications where long-term efficiency is more important than initial costs, which can be higher for this type of gear reducer (although in-line reducers are less expensive than parallel shaft reducers).

-

Realistic, Hands-On Mechanical Drives TrainingItem Number:205-130

The In-Line Helical Gear Reducer Dissectible is a sturdy unit mounted on a 7-gauge, formed-steel baseplate with provision for bench-top, workstation, or storage rack mounting.

-

Realistic Hands-On TrainingItem Number:205-255

In-line helical gear reducers have a unique set of benefits. They’re useful in higher horsepower applications where long-term efficiency is more important than initial costs, which can be higher for this type of gear reducer (although in-line reducers are less expensive than parallel shaft reducers). In addition to being highly efficient, in-line helical gear reducers are capable of handling higher overhung loads.

-

Real-Life Gear Reducer TrainingItem Number:205-285

DAC Worldwide's In-Line Planetary Gear Reducer Cutaway (205-285) is a sectioned industrial gear reducer for use in classroom and laboratory training relating to mechanical drives.

-

Cooling Tower Maintenance TrainingItem Number:298

DAC Worldwide’s Induced Draft Cooling Tower Model (298) is a highly-detailed scale model of a common open circuit, induced draft, cooling tower, supporting training in the operation and maintenance of cooling towers, as found in utility systems within both industrial facilities and commercial installations.

-

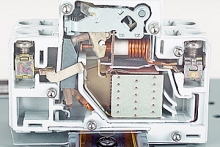

Real-World Electrical Training AidItem Number:273-905

DAC Worldwide’s 2-Pole Circuit Breaker Cutaway (273-905) is a double pole, DIN rail-mounted, single-phase industrial breaker that has been carefully sectioned so that learners can see the internal configuration of the breaker.

-

DAC Worldwide’s Journal and Fluid-Film Bearing Trainer (204J-000) is a realistic, heavy-duty learning aide that allows for convenient and consistent training in the identification, installation, removal, and maintenance of a variety of babbet-type journal bearings found on high horsepower, high-speed rotating machines that have high loads.Item Number:204J-000

Tech-Labs technical training solutions.

-

Installation and MaintenanceItem Number:204J-PAC

DAC Worldwide’s Journal and Fluid-Film Bearing Training System Plus (204J-PAC) is a realistic, heavy-duty learning aide that allows for convenient and consistent training in the identification, installation, removal, and maintenance of a variety of babbet-type journal bearings found on high horsepower, high-speed rotating machines that have high loads.

-

Complete to-scale replication of typical plate-type heat exchangerItem Number:288

DAC Worldwide’s Kettle Type Reboiler Heat Exchanger Training Model (288) depicts a highly-detailed scale model of a kettle-type reboiler in a technically-accurate, professionally-crafted design that supports training in the operation and maintenance of industrial heat exchangers.