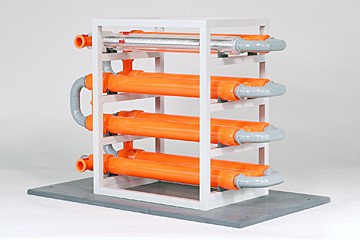

Annular Tube Heat Exchanger Model

Concentric tube heat exchangers work by passing fluid streams of different temperatures parallel to each other, separated by a pipe. This design induces forced convection, which transfers heat to/from a product.

These heat exchangers have both a simple design and a robust build that allows them to withstand high-pressure operations. They’re common in a variety of industries and are often used for material processing, food preparation, and air conditioning.

DAC Worldwide’s Annular Tube Heat Exchanger Model (281) is a highly-detailed scale model of a common annular tube (tube-in-tube) heat exchanger. The model provides realistic training in the operation and maintenance of industrial heat exchangers.

Industry-Standard Components Provide Realistic, Hands-On Training

Technical training is most effective when learners can gain hands-on practice with industry-standard components they’ll encounter on the job. The Annular Tube Heat Exchanger Model features a wide variety of common, industrial-quality components and instruments to provide learners with a realistic training experience that will build skills that translate easily to the workplace.

The model is based on the design of common industrial heat exchangers from well-known manufacturers. It’s a complete, scaled replica of typical annular tube and concentric tube industrial heat exchangers.

The model incorporates cut-away areas that illustrate the flow paths and various internal details. Included features and components include one 1-1/4” clear acrylic, fully-detailed exchanger shell with representative nozzles, expansion bellows, corrugated inner tube, and flow arrows; and seven representative opaque companion exchanger tubes with connecting tube-side and shell-side piping, depicting a counter-flow arrangement.

The Annular Tube Heat Exchanger Model features a durable PVC baseplate with provision for tabletop mounting or mounting on related DAC display and support structures. For example, the model can also be used on an optional DAC Worldwide Mobile Display Stand (902V) for greater convenience.

Features and Specifications

- Exact, "to-scale" construction throughout.

- Representative support structure.

- Based on designs of industry leaders for industrial relevancy.

- One 1-1/4", clear acrylic, fully-detailed exchanger shell with representative nozzles, expansion bellows, corrugated inner tube, and flow arrows.

- 7 representative opaque companion exchanger tubes with connecting tube-side and shell-side piping, depicting a counter-flow arrangement.

- Durable PVC baseplate with provision for tabletop mounting, and mounting on related DAC Worldwide display and support structures.

- Packaging for shipment via motor freight.

- Dimensions: (LxWxH) 11in. x 19in. x 13in.

- Weight: 7 lbs (Shipping weight 33 lbs)

More Information

Manufacturing & Engineering

Our learning programs develop job-ready skills that have been proven time and again. Take a look at how we can help you be successful!

Our learning programs develop job-ready skills that have been proven time and again. Take a look at how we can help you be successful!

Colleges are challenged to offer courses whenever students are available – and frequently, wherever they are available. Students want courses that are available on campus as well as from home while also providing strong hands-on skills for the technology demands facing them. Meeting these demands is no small task.

Amatrol has learning programs that allow colleges to excel in this demanding environment. We offer a full range of learning systems, both in a traditional equipment lab setting as well as in a virtual lab, that meet and exceed students' expectations.