Basic mechanical maintenance skills are fundamental throughout advanced manufacturing and industries from pharmaceutical and automotive to power and energy and agriculture. For example, industrial maintenance technicians must possess essential knowledge and skills to install, align, troubleshoot, and repair a wide variety of gears, shafts, and bearings.

Mechanical Drives

DAC Worldwide's mechanical drives training systems offer a variety of hands-on training solutions or provide an ideal skill assessment tool. These systems provide hands-on skills for gears, bearings, vibration analysis, alignments, and more.

-

Hands-On Gear Installation/Alignment TrainingItem Number:205-000

-

Gear Installation & Alignment TrainingItem Number:205-PAC

Basic mechanical maintenance skills are fundamental throughout advanced manufacturing and industries from pharmaceutical and automotive to power and energy and agriculture. For example, industrial maintenance technicians must possess essential knowledge and skills to install, align, troubleshoot, and repair a wide variety of gears, shafts, and bearings.

-

DAC Worldwide’s Journal and Fluid-Film Bearing Trainer (204J-000) is a realistic, heavy-duty learning aide that allows for convenient and consistent training in the identification, installation, removal, and maintenance of a variety of babbet-type journal bearings found on high horsepower, high-speed rotating machines that have high loads.Item Number:204J-000

Tech-Labs technical training solutions.

-

Installation and MaintenanceItem Number:204J-PAC

DAC Worldwide’s Journal and Fluid-Film Bearing Training System Plus (204J-PAC) is a realistic, heavy-duty learning aide that allows for convenient and consistent training in the identification, installation, removal, and maintenance of a variety of babbet-type journal bearings found on high horsepower, high-speed rotating machines that have high loads.

-

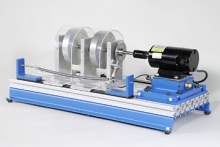

Hands-On Design, Installation & Alignment SkillsItem Number:221-000

DAC Worldwide’s Linear Drives Training System (221-000) is a benchtop device that facilitates training in the design, function, installation, and alignment of common linear drive components. Fabricated from steel and aluminum, the training aid combines a variety of common industrial components and installation scenarios in one assembly.

-

Teach Mechanical Skills Hands-OnItem Number:207-000

DAC Worldwide’s Vertical Coupling/Shaft Alignment Training System (207-000) is a heavy-duty, precision learning system that allows for convenient, realistic training in shaft alignment. When paired with a variety of hands-on exercises, the system creates a complete performance-based course in the maintenance of shaft alignment.

-

Practice Hands-On Mechanical Skills for Various ApplicationsItem Number:207-PAC

DAC Worldwide’s Vertical Coupling/Shaft Alignment Training System Plus (207-PAC) is a heavy-duty, precision learning package that allows for convenient, realistic training in shaft alignment. When paired with a variety of hands-on exercises, the training system creates a complete performance-based course in the maintenance of shaft alignment.

-

Rotating Machinery Vibration TroubleshootingItem Number:203-000

DAC Worldwide’s Vibration Analysis Training System (203-000) is a heavy-duty learning package that allows for in-depth training in vibration analysis, using a vibration meter, gear/belt drives, and bearing faults.

-

Rotating Machinery Vibration TroubleshootingItem Number:203-PAC

DAC Worldwide’s Vibration Analysis Training System Plus (203-PAC) is a heavy-duty learning package that allows for in-depth training in vibration analysis, using a vibration meter, gear/belt drives, and bearing faults.

Pages

- « first

- ‹ previous

- 1

- 2

- 3