Amatrol’s Smart Factory Tabletop Mechatronics system provides a full mechatronics line in a small space and is a great way to introduce Industry 4.0 to high school students.

Manufacturing & Engineering

Our learning programs develop job-ready skills that have been proven time and again. Take a look at how we can help you be successful!

Our learning programs develop job-ready skills that have been proven time and again. Take a look at how we can help you be successful!

Colleges are challenged to offer courses whenever students are available – and frequently, wherever they are available. Students want courses that are available on campus as well as from home while also providing strong hands-on skills for the technology demands facing them. Meeting these demands is no small task.

Amatrol has learning programs that allow colleges to excel in this demanding environment. We offer a full range of learning systems, both in a traditional equipment lab setting as well as in a virtual lab, that meet and exceed students' expectations.

-

Smart Factory Training | Hands-On Industry 4.0 Skills

-

Experience a new era of Collaborative TechnologyItem Number:CRX 5iA | CRX-10iA | CRX-10iA/L | CRX 20iA/L | CRX 25iA

Experience the all-new CRX Series, FANUC's latest collaborative robot designed to make installation and programming your cobots easier than ever before.

-

Easy-to-Program, Classroom Ready Weld Educational CartItem Number:APTARC50

Welding programs that want to teach the latest technologies will add robotic welding to their program offering. This easy-to-program collaborative robot...

-

Teaches fundamentals of AC and DC electrical systemsItem Number:T7017A

The model T7017A includes a bench top-mount workstation, AC power supply, DC power supply, electrical components set, lead set, hand-held multimeter, circuit tester, built-in instrumentation console, electrical circuit simulation software, student learning materials for both theory and lab, and teacher’s assessment guide. This system uses industrial quality components to help students become better prepared for what they will encounter on the job.

-

Whether using one station or many, Amatrol’s Mechatronics Learning System is the ultimate team project!

Amatrol's 870 Mechatronics Learning System teaches students a broad array of job-ready skills in integrating technologies. Students work together in a team environment to make the whole process work. Seven stations make up a complete flexible manufacturing system. Each station is a small mechatronics system in itself with multiple, integrated technologies that can be used stand-alone or in various combinations, creating unlimited project capability. The Learning System is compact, enabling it to fit into almost any teaching facility.

-

Introduces the Fundamental Hydraulic PrinciplesItem Number:BH-85

Each Basic Hydraulics training system features standard industrial grade components. This attention to quality gives students experience they would normally only get on-the-job by helping them recognize industrial components and how to troubleshoot them more effectively. Components included with Basic Hydraulics are pre-mounted on circuit panels with silk-screened labels next to each, which facilitates ease of use and identification.

-

Amatrol's Basic Pneumatics training system (85-BP) introduces pneumatic principlesItem Number:85-BP

Amatrol’s Basic Pneumatics training system (85-BP) introduces pneumatic principles through a combination of Amatrol’s top-flight multimedia curriculum with hands-on industrial pneumatic skill-building. Topics covered in this learning system include single-acting cylinder circuits, pressure vs. cylinder force, and flow control valves, while the panels can be used to practice skills such as connecting and operating a needle valve to control actuator speed.

-

Modern Manufacturing Technology with a Fully Integrated and Intelligent Cell.Item Number:CSM

The CSM is an intelligent manufacturing system using the latest Industry 4.0 connected advanced manufacturing equipment and techniques to produce a promotional product you can be proud to have your name on.

-

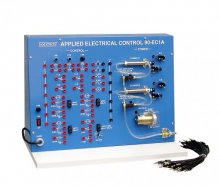

Interpret, design, and operate relay control circuits using ladder diagramsItem Number:90-EC1A

The Applied Electrical Control Learning System (90-EC1-A) teaches learners how to interpret, design, and operate relay control circuits using ladder diagrams. Electrical control is vital in the operation of electric and fluid power actuators and also forms the fundamental building block of automation systems like programmable logic controllers (PLCs), which are programmed using the electrical control schematic method, the ladder diagram.

-

Hands-On Electrical Relay Control SkillsItem Number:85-EH

The Electro-Hydraulics training system includes an electrical control panel with relay control components and an electrical valve module with solenoid-operated hydraulic directional control valves and electrical/electronic sensors. These components will be used to study a variety of topics including electrical control systems, basic control devices, power devices, control relays, sequencing control, timer control, pressure control applications, and circuit applications.